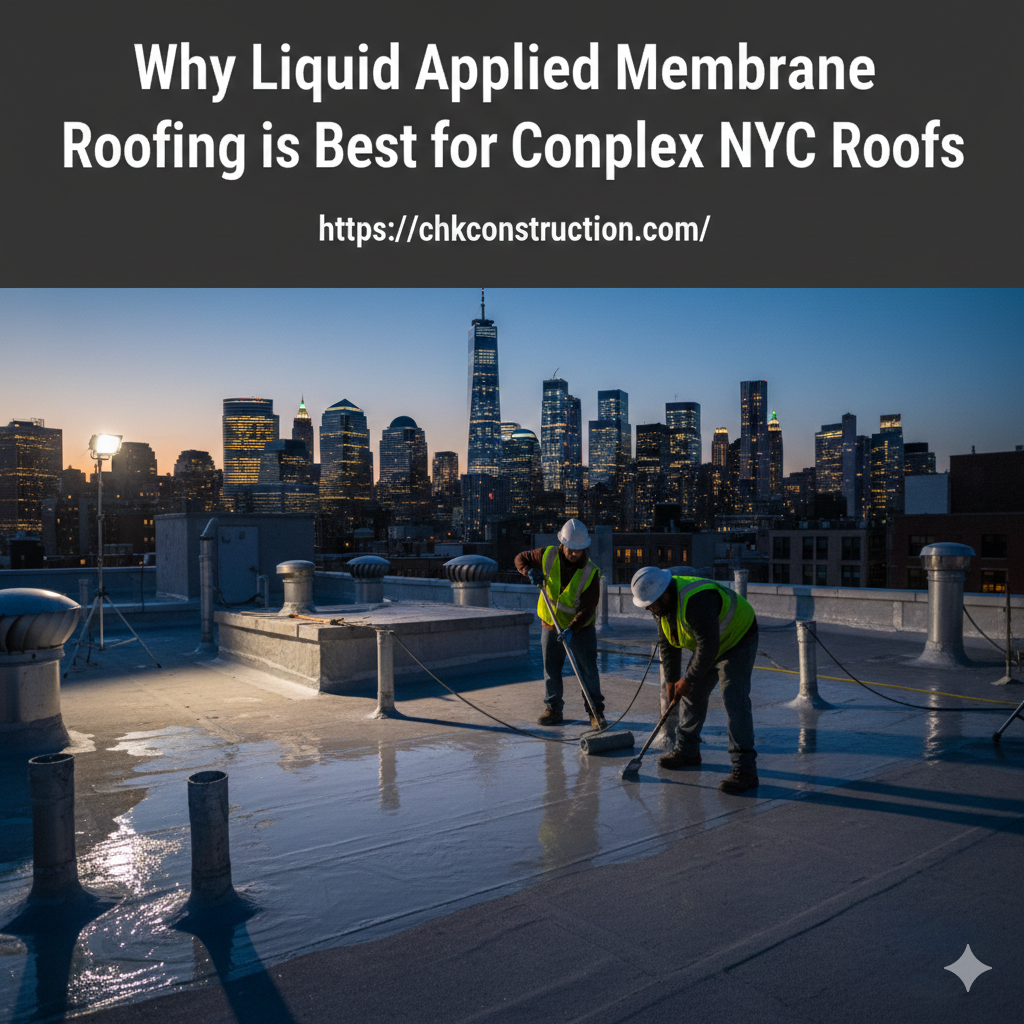

If you spend as much time on New York City rooftops as I do, you start to see a pattern. Most roofs in this city aren’t just flat, empty spaces. They are “pincushions” brimming with HVAC sleepers, gas lines, electrical conduits, vents, and satellite mounts.

In my years leading CHK Construction, I’ve seen traditional torch-down and EPDM (rubber) roofs fail time and time again in these environments. Why? Because a roof is only as strong as its seams. And when you have 50 different pipes sticking out of your roof, you have 50 different opportunities for a seam to fail.

That’s why, when a client asks me for a permanent solution for a high-traffic or high-penetration roof, I give them one answer: Liquid Applied Membranes (LAM).

The Problem with “Cutting and Pasting”

Traditional roofing is like gift-wrapping a box. It works great on a smooth surface, but try gift-wrapping a cactus. That’s essentially what you’re doing when you try to use sheet membranes around a cluster of HVAC units.

Every time a roofer has to cut a piece of rubber to fit around a pipe, they create a joint. In NYC, where the temperature swings from 100°F in July to 10°F in January, those joints expand and contract. Eventually, the caulk or the tape gives way.

Enter the Liquid Revolution

Liquid membrane roofing in NYC is a game-changer because it’s applied as a fluid and cures into a single, monolithic, rubber-like sheet.

- Seamless Integrity: There are no seams to fail. The membrane literally “self-flashes” to every pipe and corner.

- Cold-Applied Safety: We don’t use torches. In a dense city like NYC, where fire insurance and safety are top priorities, a flame-free application is a massive advantage.

- Fully Bonded: Unlike “loose-laid” systems, liquid membranes are fully adhered to the substrate. If you ever get a puncture, water can’t travel underneath the membrane to cause a “mystery leak” ten feet away.

Why We Specialize in Kemper System Repair?

When it comes to liquid membranes, the Kemper System is the gold standard we swear by. Whether we are doing a new installation or a Kemper System repair, the performance is unmatched.

Kemper is a fleece-reinforced, high-performance resin (usually PMMA or Polyurethane). It’s what we use for the most sensitive areas:

- Mechanical Rooms: Where vibration and heat are constant.

- Plaza Decks: Where you’re putting heavy pavers or a green roof on top and can’t afford a leak.

- Historic Landmarks: Where you need to waterproof intricate cornices or moldings that a sheet membrane could never touch.

Yes, it is a premium product. But when you factor in that we often don’t have to do a full tear-off of the old roof (saving you thousands in disposal fees), the ROI is incredible.

The CHK Difference: The “Penetration” Experts

At CHK Construction, we don’t just “paint” a roof. Liquid-applied roofing is a highly technical “wet-on-wet” process. It requires precise mixing, the right ambient temperature, and expert fleece placement.

We’ve seen what happens when an inexperienced crew tries to save money on the resin: it ends up peeling like a bad sunburn. We do it right the first time, so you don’t have to see us again for 25 years.

FAQs

How long does liquid applied membrane roofing last?

When properly installed and reinforced with fleece (like the Kemper System), these roofs typically last 20 to 30 years. Because they are UV-stable and don’t have seams, they outlast almost every other flat roofing material on the market.

Can you apply a liquid membrane over an existing roof?

Yes! This is one of its biggest perks. As long as the existing substrate is structurally sound and dry, we can often apply a liquid membrane directly over old modified bitumen, TPO, or even metal. This eliminates the noise, dust, and cost of a total tear-off.

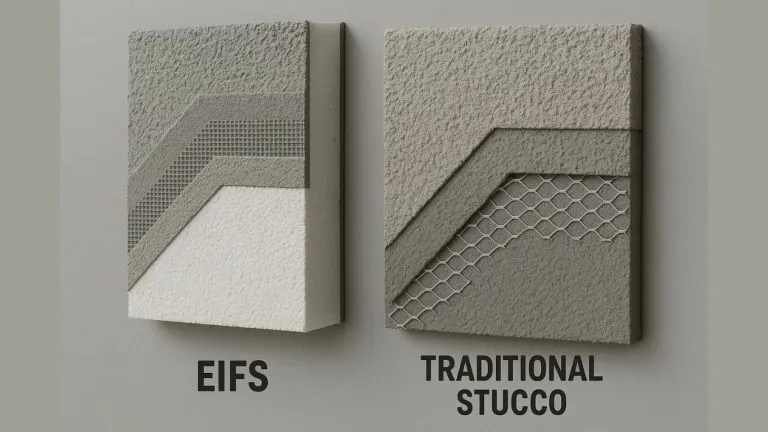

What is the difference between a roof coating and a liquid-applied membrane?

This is a big one. A coating is a thin layer designed to extend the life of a healthy roof. A liquid-applied membrane is a thick, reinforced structural waterproofing system. One is a cosmetic fix; the other is a full-scale roofing solution.

Is Kemper System worth the extra cost?

In NYC, absolutely. While the initial material cost is higher, you save significantly on labor (no complex flashing), disposal (no tear-off), and future repairs. For a “complex” roof with many penetrations, it is actually the most cost-effective long-term choice.

Stop Patching Your Leaks. End Them.

If your building has a roof that looks like a forest of pipes and HVAC units, stop trying to fix it with tar and tape. Let’s look at a seamless liquid solution that actually works.

Is your complex roof ready for a 25-year solution? Contact CHK Construction for a Liquid Membrane Audit We specialize in high-tech waterproofing for NYC’s toughest rooftops.