In the Tri-State area, where winter temperatures can plunge quickly, every commercial or structural concrete pour presents a unique set of challenges. When the ambient temperature drops, the process of mixing, pouring, and curing concrete becomes significantly more complex and risky.

Ignoring these challenges is not an option. If fresh concrete is exposed to freezing conditions during its critical early setting phase, the structural integrity of the entire slab can be compromised by up to 50%.

For developers, site managers, and contractors operating in New York and New Jersey, mastering cold weather concreting standards ACI is paramount to delivering a durable, long-lasting, and structurally sound asset.

In This Essential Technical Guide, You Will Learn:

- The Regulatory Definition of “Cold Weather”: Understanding the specific temperature thresholds set by the American Concrete Institute (ACI) that trigger special winter protocols.

- The Critical 24-Hour Window: Why freezing during the initial setting period can lead to brittle concrete and massive strength loss.

- Essential Preparation Tips: Mandated best practices, including preheating aggregates and water, to ensure the concrete leaves the plant at an appropriate temperature.

- Protection Protocols: Techniques for protecting fresh concrete from freezing and mitigating the risks associated with the Tri-State area’s relentless freeze-thaw cycles.

- Long-Term Durability: Advice on finishing, sealing, and avoiding de-icing salts to prevent scaling and spalling on exterior slabs.

I. The Threat: Structural Failure and the ACI Definition

A. What is “Cold Weather Concreting”?

The American Concrete Institute (ACI) defines cold weather concreting as: “a period when for more than three successive days the average daily air temperature drops below 40 degrees Fahrenheit and stays below 50 degrees Fahrenheit for more than one-half of any 24-hour period.”

Concrete cures best between 50°F and 60°F. When temperatures fall below this range, the exothermic reactions necessary for curing slow down significantly.

B. The Freeze Damage Risk

The most devastating damage occurs during the critical first 24 hours after the pour. If fresh concrete is allowed to freeze before it has achieved the strength to tolerate the expansion of ice, the water within the mix freezes, expands, and leaves the concrete weak and brittle.

The final structural strength of the asset may be reduced by up to 50%, requiring costly remediation or total replacement—a severe risk that can be entirely mitigated with proactive measures.

II. A Contractor’s Cold Weather Preparation Checklist

When pouring concrete in winter conditions, success hinges on meticulous planning and adherence to temperature control protocols both before and after the pour.

A. Preparation Tips: Heating the Mix

To ensure the concrete reaches the required temperature for effective curing (around 50-60°F), preparation must start before the mix leaves the plant:

- Preheating Components: Ready-mix companies can preheat the water and aggregates (components of the mixture) to ensure the concrete leaves the plant at an appropriate temperature, typically around 65°F.

- On-Site Storage: Ensure that any small amounts of aggregates or water mixed on-site are stored in warm indoor locations or mixed with hot water.

- Protecting the Base: The ground and any surfaces the concrete will contact should be free of ice, snow, and large amounts of standing water.

B. Protection Protocols: The First 24 Hours

Once the concrete is placed and finished, the focus immediately shifts to protecting fresh concrete from freezing.

- Insulation & Curing: Use insulating blankets, straw, or heated enclosures (like temporary heated tents or tarps) to maintain the required temperature on the surface and prevent rapid heat loss.

- Monitoring: Continuous temperature monitoring is essential to confirm that the exothermic curing reactions are progressing and the internal temperature remains within the safe range (above freezing).

III. Long-Term Durability: Preventing Seasonal Damage

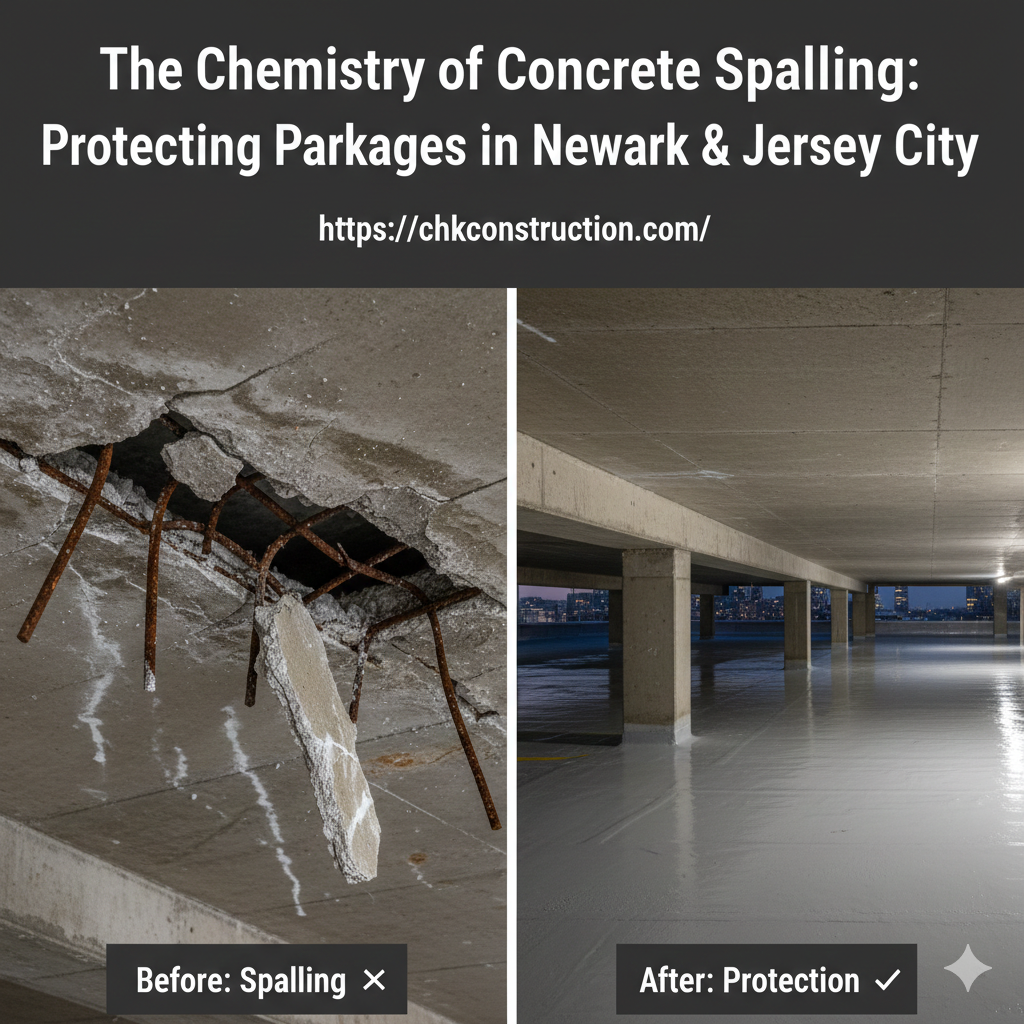

Even after the initial cure, exterior concrete in the Tri-State area is subject to seasonal freeze-thaw conditions, making it prone to spalling (flaking) and scaling.

To ensure long-term durability and structural integrity:

- Seal It Up: Applying a high-quality concrete sealer is the most effective way to prevent water penetration, which is the root cause of frost damage.

- Ensure Proper Drainage: Make sure the surrounding grade ensures that water drains away from the concrete slab, preventing pooling near edges.

- Use Salt Sparingly: While useful for preventing slips, the excessive use of de-icing salts can severely damage concrete surfaces, making them brittle and increasing the likelihood of cracks and flaking.

- Address Cracks Early: Even minor cracks must be sealed immediately, as they allow water ingress, which exacerbates damage upon subsequent freezing.

Do not compromise the structural integrity of your commercial asset this winter. CHK Construction utilizes ACI-compliant protocols and advanced techniques to ensure every concrete pour is a durable, long-term success. Contact us today to discuss your winter construction needs.